February 14, 2026

If you live in Cape Coral, Fort Myers, Estero, or Bonita Springs, you already know the truth: a fence can look perfect on install day and still fail in a big blow. That is why fence wind ratings get so much attention, especially for privacy panels.

Here is the catch. Most problems are not caused by the panel alone. Wind failure usually starts at the posts, footings, fasteners, and gates. Think of a fence like a chain, it holds only as well as its weakest link.

This guide breaks down what matters in 2026, what paperwork actually proves compliance, and what to ask for in contractor bids.

What "fence wind ratings" mean in Southwest Florida (and what they don't)

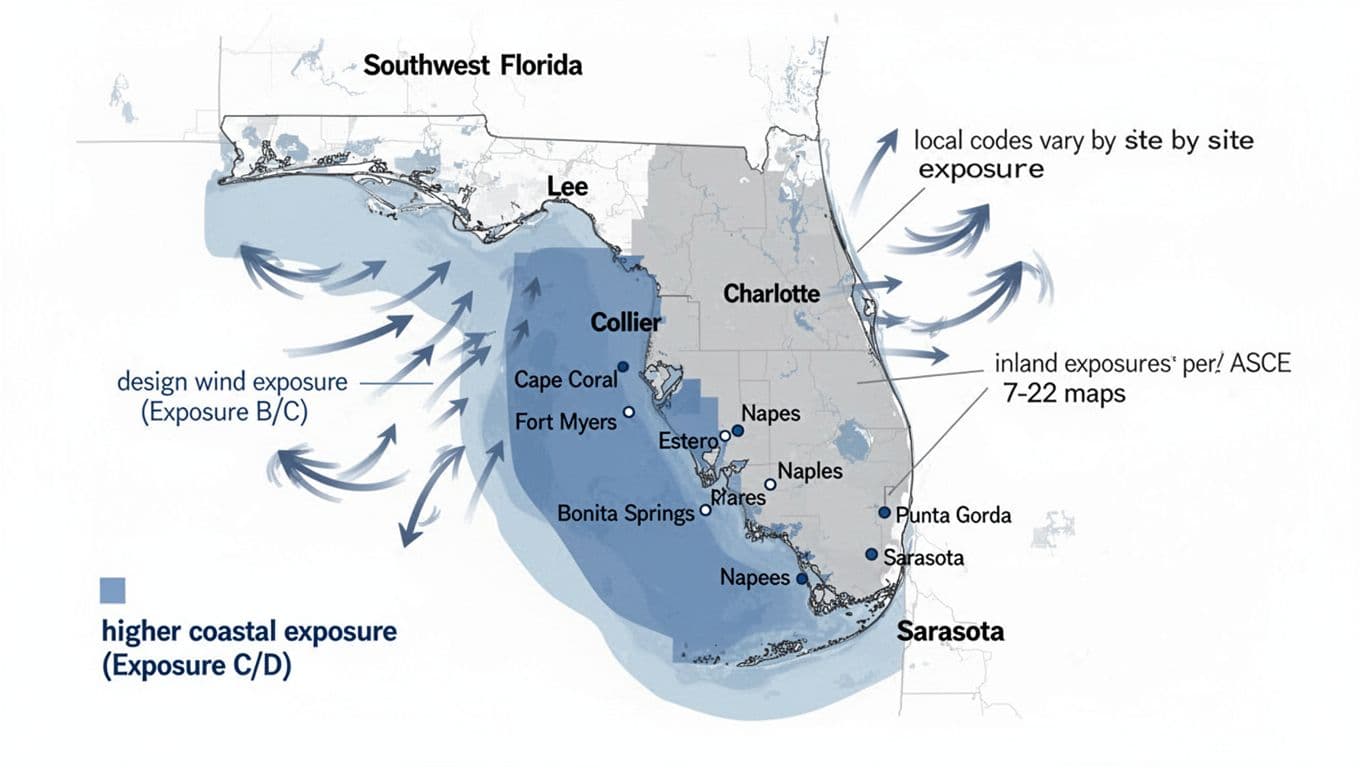

Map-style diagram showing how coastal exposure vs inland exposure can change fence design pressures, created with AI.

Map-style diagram showing how coastal exposure vs inland exposure can change fence design pressures, created with AI.

A wind rating claim often sounds simple: "This panel is rated for hurricane winds." In real permitting and real storms, the question is different: can the installed fence system resist the design wind pressures for your site?

In 2026, wind design in Florida ties back to the Florida Building Code and ASCE 7 methods. Designers start with wind speed maps, then convert that into pressures based on factors like height, exposure, and how open the terrain is. Open canal lots and wide intersections can behave more like open terrain, which increases pressure on a solid fence.

That is why a "rated panel" by itself is not the finish line. A fence is a structure made of connected parts, and wind loads travel through the whole assembly: panel to rails, rails to posts, posts into concrete, concrete into soil.

If you want a local, permit focused example of what reviewers ask for, Lee County publishes a helpful checklist style guide for residential fence permits: Lee County's Residential Fence Guide (PDF).

The number on a brochure matters less than the details on the plan: post size, spacing, embedment, concrete, and hardware.

For code context, Chapter 16 is where the Florida Building Code lays out how structural wind design is addressed: Florida Building Code structural design chapter.

Posts, embedment, concrete, and fasteners: the real drivers of wind performance

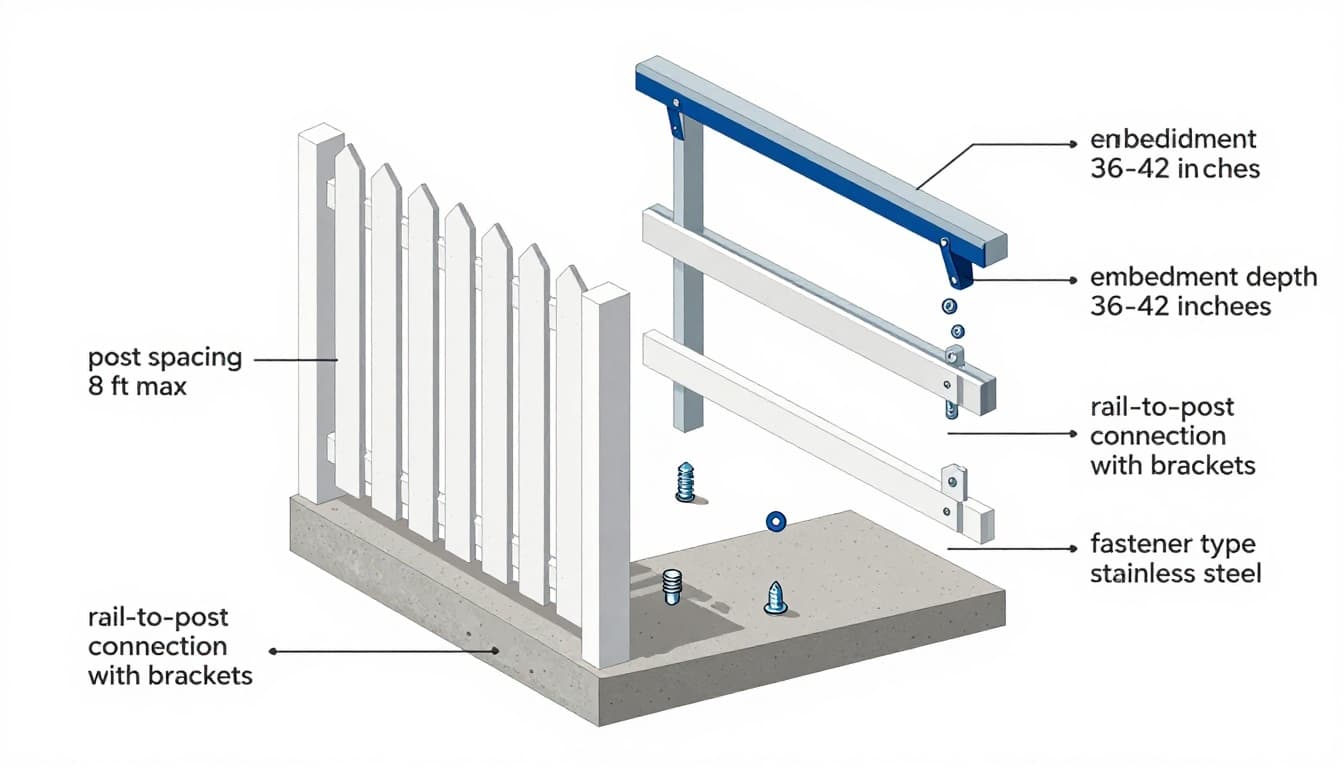

Exploded fence diagram highlighting the parts that control wind performance, created with AI.

Exploded fence diagram highlighting the parts that control wind performance, created with AI.

In Southwest Florida, fences usually fail in one of three ways: posts lean, connections tear out, or gates rack and pull hardware loose. Each failure has a boring cause, and boring is good because you can plan for it.

Posts and spacing. Taller fences and solid privacy styles act like sails. Wider post spacing increases deflection, which increases stress at every connection. Even with a premium panel, thin posts or long spans can turn into a wobble problem fast.

Embedment and soil. Sandy soils and high water tables change everything. A shallow set post can feel solid for months, then loosen after repeated wet season cycles. Deep embedment and properly sized footings resist overturning, not just side push.

Concrete quality. Concrete is not just "a bag in a hole." Strength comes from correct mix, adequate volume, and time to cure. Weak, wet soup concrete can shrink and crack, leaving a post that rocks in the socket. Contractors should also keep the post plumb while curing, especially on gate posts.

Fasteners and corrosion resistance. Salt air, sprinklers, and fertilizer overspray attack hardware first. Look for stainless steel where it counts (hinges, latches, brackets, screws), or at minimum hot-dipped galvanized hardware matched to treated lumber when used. Cheap electroplated screws can rust quickly and snap under cyclic loading.

Material choice still matters, but install details decide the outcome. If you are weighing styles, these pages can help you match material to local conditions: vinyl fencing in Cape Coral and aluminum fencing in Southwest Florida.

Gates and corners: where wind damage usually starts

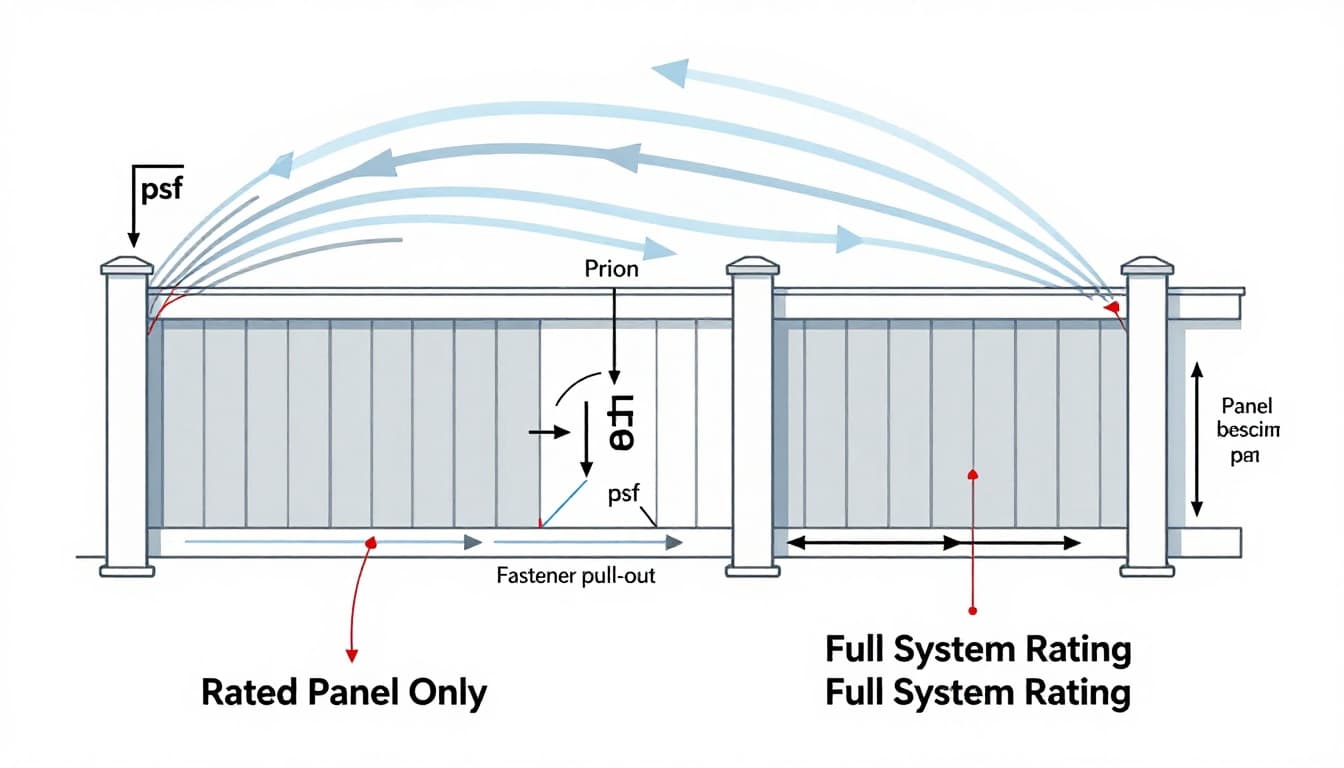

Wind load schematic showing pressure, suction, and common failure points, created with AI.

Wind load schematic showing pressure, suction, and common failure points, created with AI.

A straight fence run is rarely the first thing to go. Corners, ends, and gates take concentrated forces, then the rest follows.

Gates are the biggest repeat offender because they add weight and motion. Wind does not just push a gate, it twists it. That twist loads the hinge screws, then the hinge post, then the footing. If the gate frame lacks a diagonal brace (or an internal steel frame on vinyl), sagging starts early and gets worse after every storm.

Corners need the same attention. When a long run racks in wind, the corner post becomes a lever. Extra bracing, stronger posts at corners, and hardware that does not loosen are what keep lines straight.

If you want a practical overview of storm oriented options and where systems fail, this guide is a solid starting point: hurricane-resistant fencing options for Cape Coral homes. For a local comparison mindset (privacy vs wind-through styles), see vinyl vs aluminum in Cape Coral storms and sun (2026).

Panel rating claims vs system performance factors (and a bid spec you can paste)

Before you pick a contractor, it helps to separate marketing claims from what inspectors and engineers can verify.

| Panel rating claims | System performance factors |

|---|---|

| "Panel is hurricane rated" | Wind design is based on site exposure , height, and pressure, not panel marketing alone |

| "Rated panel" documentation | Stamped calculations or engineering letter may be needed for taller fences or exposed sites |

| Stronger panel thickness | Post size and spacing control bending and deflection across the whole run |

| "Wind-resistant hardware included" | Fastener type and corrosion resistance (stainless or hot-dipped galvanized) controls long-term holding power |

| "Meets Florida code" | Plans must show embedment depth, footing size, concrete strength , and gate/corner details |

Now for the practical part. Copy and paste the template below into your quote request so bids are apples to apples.

Homeowner fence spec template (Southwest Florida, 2026)

- Fence type and height: ______ (ex: 6-foot privacy vinyl, or 4-foot aluminum picket)

- Layout: include a sketch showing corners, ends, and total linear footage

- Post schedule:

- Line posts: size ______, material ______

- Corner/end posts: upsized to ______

- Gate hinge/latch posts: upsized to ______, reinforced as required

- Post spacing: maximum ______ feet on center (state any tighter spacing on long runs)

- Embedment and footings:

- Minimum embedment depth: ______ inches (note if deeper near canals or soft soils)

- Minimum footing diameter: ______ inches

- Concrete: specify minimum strength or mix standard: ______

- Connections and fasteners:

- Rail to post connection method: routed, bracketed, or welded: ______

- Hardware: stainless steel preferred for hinges, latches, and exposed screws; otherwise hot-dipped galvanized: ______

- Dissimilar metal isolation (if needed): ______

- Gates:

- Gate width(s): ______

- Frame: welded metal frame or diagonal brace required: ______

- Hinges: heavy-duty, through-bolted if applicable: ______

- Latch: self-latching, lockable: ______

- Drop rod/cane bolt for double gates (if any): ______

- Submittals with bid:

- Product data sheets for fence system: ______

- Installation details drawing: ______

- Engineering calcs or letter if required by jurisdiction or height: ______

- Permitting:

- Contractor to confirm local permit requirements and handle permit/inspections: yes/no

Disclaimer: Fence requirements vary by municipality, neighborhood rules, exposure category, soil conditions, and fence height. Always confirm requirements with your local building department and use a Florida-licensed engineer when the project or permitting office calls for it.

Conclusion

In Southwest Florida, fence wind ratings only matter when they describe the whole installed system, not just a panel. Focus on posts, embedment, concrete, corrosion resistant fasteners, and gate bracing, because that is where fences usually fail. If your bid request forces clear details, you will get better quotes and a fence that stays put when the weather turns.