February 3, 2026

If you’ve ever tried to push a beach umbrella into dry sand, you already understand Southwest Florida fencing. It feels firm for a moment, then the first hard gust makes it wobble. A fence is the same idea, just with higher stakes.

In Cape Coral, Fort Myers, Estero, and Bonita Springs, fence post depth isn’t just a “do your best” detail. Sandy soils, a high seasonal water table, and storm wind loads punish shallow posts and sloppy concrete work fast. This guide breaks down what holds up, what fails, and the reasons behind it, with practical install steps you can follow.

Why sandy soil and a high water table change everything

Southwest Florida sand has low “grab.” Clay has cohesion, it sticks to itself. Sand mostly relies on friction and confinement. That matters because most fence damage isn’t a straight upward pull, it’s lateral force, wind pushing on panels, gates tugging, and people leaning.

Here’s the basic physics in plain terms:

- Lateral resistance comes from depth and diameter. The deeper the post, the more sand is pressing against it, which increases resistance to bending and rocking. A wider footing also spreads the load and fights rotation.

- Saturation weakens the sand’s hold. When the water table rises after heavy rain, sand can behave more like a loose slurry. Water reduces effective pressure between grains, so posts can move more easily. You also get hole wall collapse while digging, which leads to backfilled voids and soft spots.

- Uplift is real in storms. A privacy fence acts like a sail. When wind hits, the post wants to rotate and can also lift slightly on the “downwind” side. If the footing is too small or too smooth, the post can slowly pump loose over time.

If you live near the coast or in regulated dune areas, there may be special permit rules for sand fencing and related work. The state’s Florida DEP CCCL sand fence guidelines are a good example of how strict coastal requirements can get. For backyard fences, local city and county rules still apply, and wind exposure can change what’s required. For material choices designed for storms, see best hurricane-proof fences in Southwest Florida.

Fence post depth and footing sizing that actually holds in Florida sand

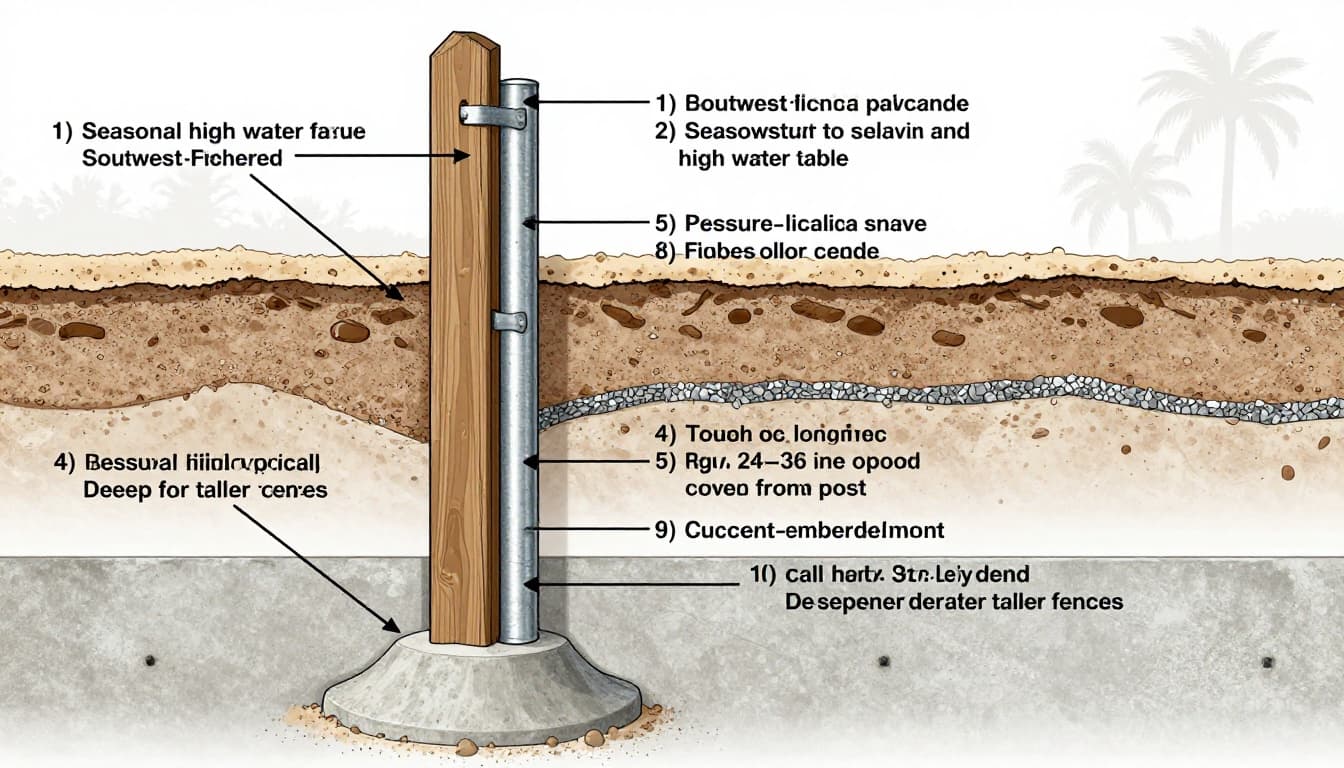

Cutaway showing a strong post embedment, bell-shaped footing, drainage option, and a crowned top to shed water (created with AI).

Most “it failed” stories start with a post that’s too shallow, a hole that’s too narrow, or concrete that was poured like a straight-sided plug. In sand, you want a post system that resists rocking.

A solid rule of thumb is the one-third rule (bury about one-third of the above-ground height). Many installers push toward one-half in very loose sand, for gates, and for taller privacy fences. For a quick reference, compare this with an Angi fence post depth calculator , then adjust for your site (wet sand often needs more).

| Fence height above grade | Typical post embedment in SWFL sand | Common hole diameter (line posts) | Gate/corner note |

|---|---|---|---|

| 4 ft | 18 to 24 in | 10 to 12 in | Gates often 24 to 30 in |

| 6 ft | 24 to 36 in | 12 to 16 in | Gates often 36 in |

| 8 ft | 36 to 48 in | 16 to 20 in | Gates often 42 to 48 in |

When concrete helps, and when it hurts

Concrete helps when it’s big enough, deep enough, and shaped to fight rotation. In sand, a bell-shaped bottom (wider at the base) acts like an anchor. A straight, narrow plug often “polishes” loose sand around it and can rock.

Concrete can hurt when it traps moisture against wood. In wet sand, water sits along the post and footing interface, and wood rots right at the concrete line. Two fixes matter most:

- Form a crowned top of concrete that slopes away from the post so rain runs off.

- Keep wood protected: use a rated post, seal cut ends, and consider a barrier wrap or sleeve where the post meets concrete.

If you want help selecting a system that fits your yard and wind exposure, start with professional fence services for Cape Coral properties.

A practical install method, plus a checklist for common failures

Side-by-side options for sand when concrete is not ideal, including driven posts and helical anchors (created with AI).

Step-by-step: setting posts in sandy soil (with concrete done right)

- Call 811 before you dig. Utilities in SWFL can be shallow, and repairs get expensive fast.

- Lay out the fence line and mark posts. Keep spacing consistent with your panel system, and plan extra strength at corners and gates.

- Dig the hole to full depth first. In wet sand, holes can slump; work in short sections and don’t leave open holes overnight.

- Widen the bottom slightly. A subtle bell shape increases pull-out and rotation resistance.

- Add a drainage layer if the hole stays wet. A few inches of clean gravel can reduce standing water under the post.

- Plumb and brace the post. Don’t “eyeball it.” A small lean becomes a big lean later.

- Pour concrete and crown the top. Keep the top slightly above grade and slope it away from the post.

- Backfill and compact around the outside (if needed). Loose backfill settles in sand, so compact in lifts.

Troubleshooting checklist: what failed, and the usual cause

- Post wobbles after a few storms : shallow embedment, narrow hole, or a straight-sided plug that’s rocking.

- Fence leans in one direction : posts set out of plumb, or wind load exceeds the footing size.

- Rot at the ground line : water trapped at the concrete-to-wood line, no crown, or unsealed cuts.

- Gate sags quickly : gate posts not deep enough, footing not wide enough, or hardware pulling on soft posts.

- Concrete cracks around the post : too wet a mix, poor consolidation, or movement from undersized footing.

- Holes collapse during digging : high water table and loose sand, dig smaller sections and set posts sooner.

Good alternatives when concrete isn’t the best fit

Driven posts can work well in sand when driven deep (often 36 to 48 inches or more). They avoid a wet concrete pocket, but they require the right equipment and can be tough near buried debris.

Helical ground anchors add serious uplift resistance for problem spots like gates or windy corners. They cost more, but they’re predictable in loose soils.

Galvanized steel posts (for wood or vinyl systems) reduce rot risk and stay straighter. They’re a strong choice where the water table is high for long periods.

Foam backfill systems can lock posts in place without a big concrete mass, and they shed water better than a sloppy plug. They’re not right for every fence style, so match them to manufacturer specs.

For help choosing an installer who understands SWFL soil, review what to ask a fence installer in Southwest Florida.

Conclusion

A strong fence in Southwest Florida starts below the surface. Get fence post depth right, size the footing to resist rocking, and manage water so the post base doesn’t stay soaked. If you’re unsure, treat corners and gates like structural points, because that’s where failures start. Always check local permit rules, wind exposure, HOA limits, and your fence manufacturer’s installation specs before you build.